The best alternative to epoxy resin

Find out why below.

Epoxy Resin Flooring V Interlocking Floor Tiles

Epoxy Resin can take a long time to cure, sometimes up to 6 weeks, meaning cracks or imperfections can appear if not cared for during that initial stage. Whereas interlocking floor tiles are quickly and easily installed, require minimal subfloor preparation and can even be installed over damp and uneven subfloors. The interlocking floor tiles don’t require any time to settle which means work can the movement of pallets trucks etc. can resume as soon as installation is finished. Experience is also needed when installing epoxy flooring solutions as time mixing and pouring the solution is essential, sometimes it’s better to seek the help of a professional especially if mistakes are made these aren’t easily rectified. Whereas interlocking floor tiles require no experience to install, it’s a very simple process if you have the right tools and common sense!

Epoxy floors can’t be installed in cold temperatures, expensive heating systems would be required to heat the room and the floor to room temperature level. Whereas interlocking floor tiles can be installed at any temperature. It is recommended to allow the tiles to acclimatise to the specific room temperature for 24 hours but this is not dependant on an exact temperature. Moisture levels can affect the durability of epoxy floors because it doesn’t breathe once it is cured so any moisture trapped underneath can be a problem when it evaporates which can lead to bubbling or cracking, resulting in the eventual need of repairing. Whereas interlocking floor tiles are extremely durable and hardwearing and come with a 15-year wear guarantee.

Applications

Check out our install and application gallery to give you an idea of the look and ability of the R-Tile Industrial flooring.

Before and After

The results don’t lie, check out this image of a before and after from a warehouse. The R-Tile is easily installed over a broken epoxy floor.

Weight & vehicle load information

This video showcases the various thickness of the Tile and what weight and vehicles they can handle in tough industrial working environments. R-Tek Manufacturing have over 20 years of experience in the industrial flooring industry and can tailor a bespoke industrial floor tile solution for you.

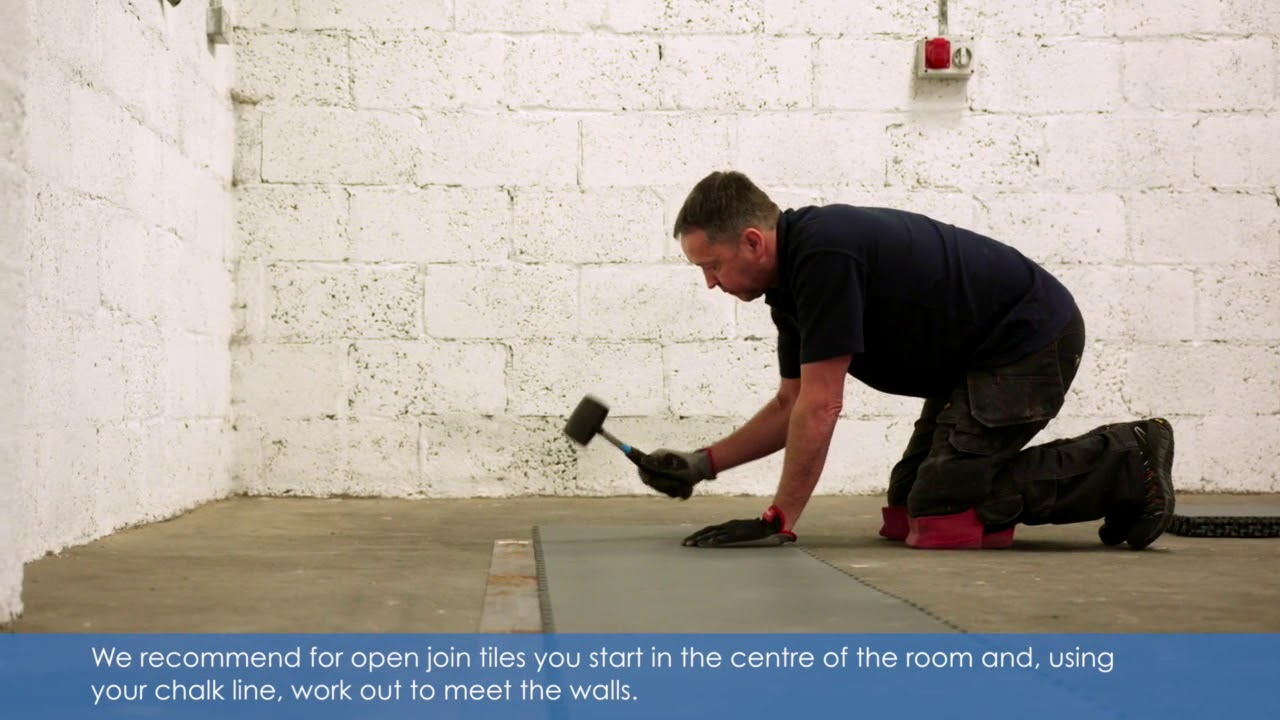

R-Tile Installation

Guide

Check out the R-Tile installation video that covers everything from the tools required to ensuring the interlocking is done correctly. For more information on how to install our industrial flooring solutions, contact us now.